Global WiEIT: Siemens Mobility 2023

Creating an overall concept for evaluating machine connectivity to the Manufacturing Execution System OPCenter at plant Brunswick.

back to project overview GWiEIT

Project

The Siemens Brunswick plant faces several challenges in its production processes, including a low degree of automation, high-quality requirements, and a mixed machine park consisting of older machines without production data acquisition (BDE). Currently, there is uncertainty about which data should be collected and stored. This project's goal was to develop a comprehensive strategy and plan for connecting the Brunswick production facility to a Manufacturing Execution System (MES).

Key elements of the project include:

- Data Identification: Identifying the relevant data points that need to be collected and stored for effective production monitoring and analysis.

- Data Storage Procedures: Establishing robust procedures for storing the collected data securely and efficiently.

- Sensor Technology: Selecting appropriate technical methods for data collection, which may involve implementing sensors and data acquisition systems on the existing machines.

- Roadmap to Implementation: Developing a detailed roadmap, including transparent prioritization that outlines the step-by-step process of integrating the MES into the production facility, considering potential challenges and timelines.

Siemens Mobility itself would like to use this concept and present it to the management group.

This work could also be relevant for industry and its sectors:

Primary sector: agriculture and forestry,

Secondary sector: industry, construction, manufacturing trades, and the

Tertiary sector: services, that are confronted with finding solutions for handling data and using it smartly in the context of digitization.

The basis for Industry 4.0 is the collection, processing, analysis and interpretation of large amounts of digital data - if possible in real time. Data collection along the entire value chain.

Project Team

Team members from left to right:

Alicia Sternkopf: B.Sc. Business Informatics (HTW)

Nicole Sandow: Bachelor of Engineering (Honours)/Diploma of Professional Engineering, Practice Major in Civil and Minor in Structures (UTS)

Angelica Allieu: B.Sc. Computer science and Business (HTW)

Mmeughaiy Nyamusa: B.Sc. Computer science and Business (HTW)

Megan Cavanagh: Bachelor of Engineering (Honours)/Diploma of Professional Engineering, Practice Major in Civil (UTS)

Project Results

From the large number of machines, 5 machines were selected in the course of the project, which we have dealt with in more detail.

Selected Machines

Flying Probe Tester

The flying probe tester serves to test the completed PCBs functionality.

Reflow Oven

Reflow soldering circuit boards in series, realised by infrared radiation.

AOI

Machine that uses image processing methods to find and report errors in printed circuit boards.

Wave Soldering Machine

Used to solder the parts of a PCB onto the boards.

Selective Soldering Machine

The SelectLine-C machine is a modular and highly precise selective soldering system by SEHO used to solder through-hole components on PCBs.

Data Acquisition

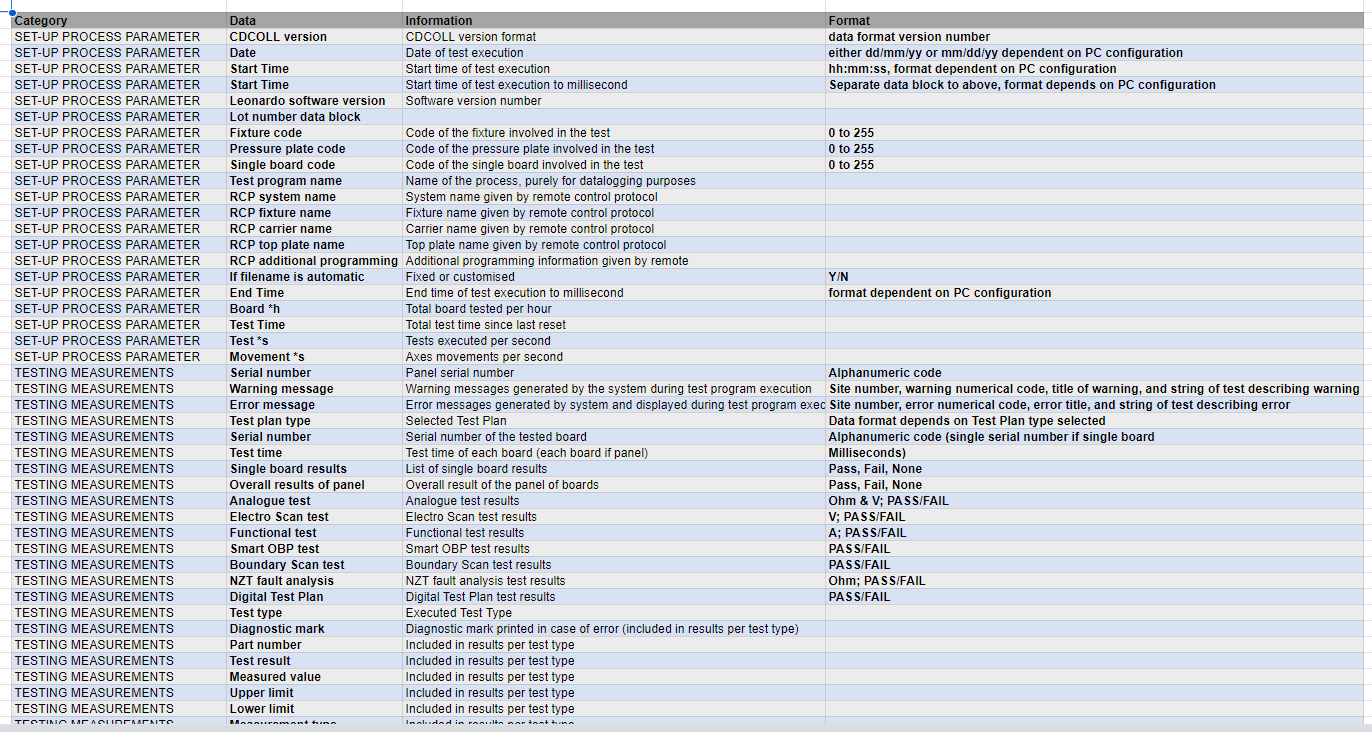

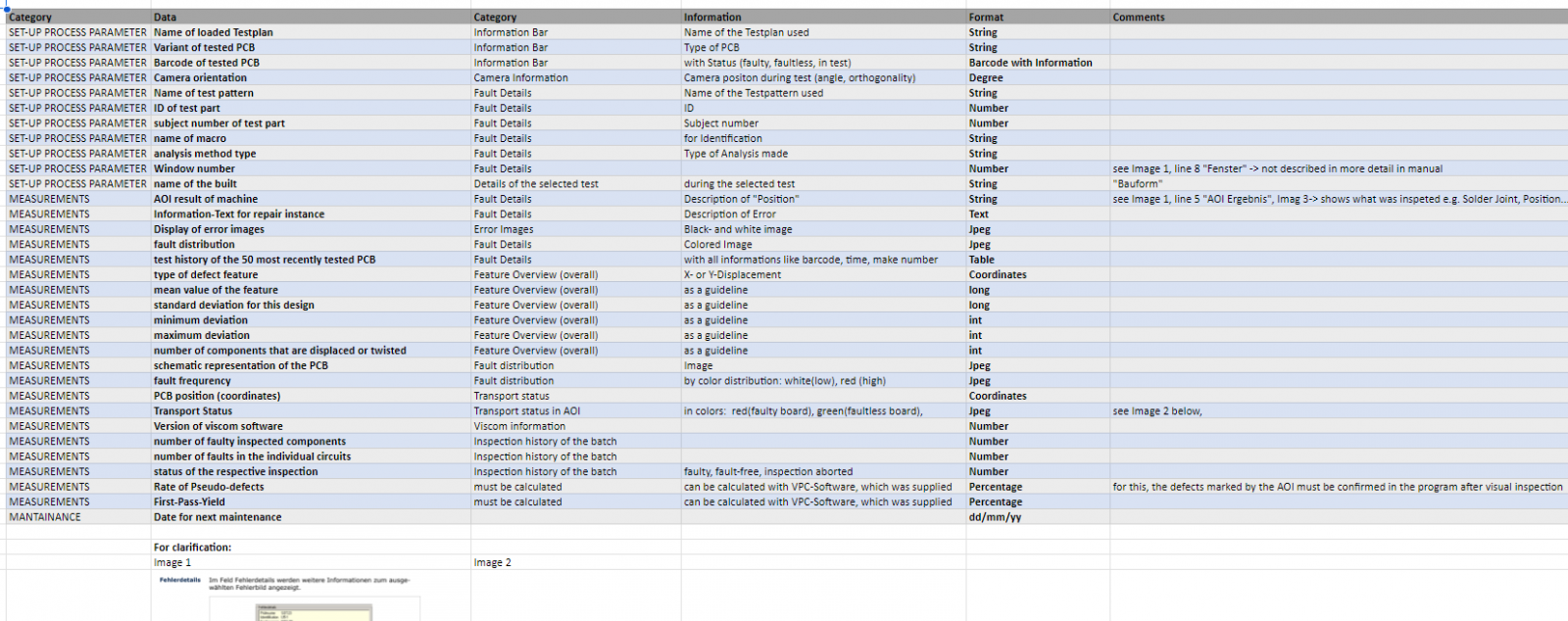

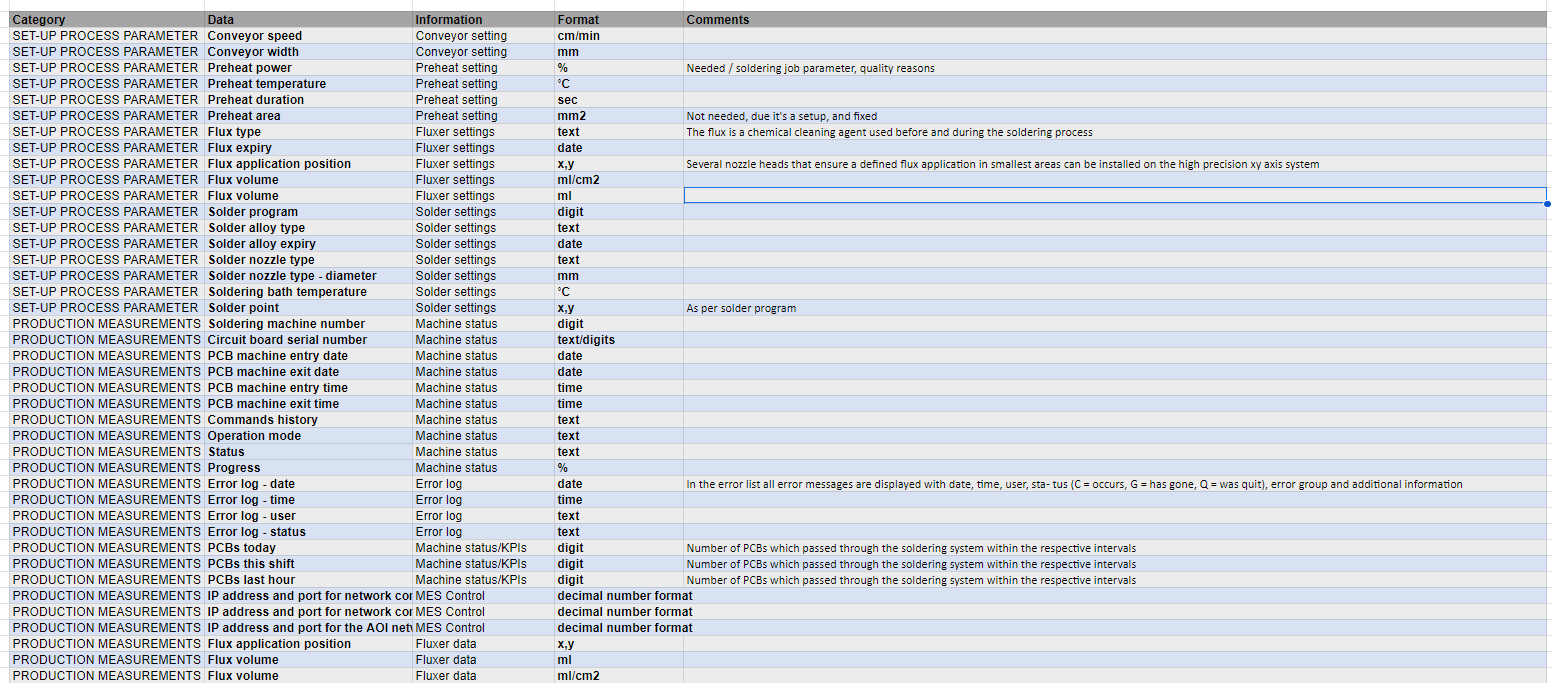

One aspect of the team’s scope included collecting all data output from the selected machines. The following tables depict an example of the data glossaries created for each machine:

Flying Probe Tester AOI

AOI

Selective Soldering Machine

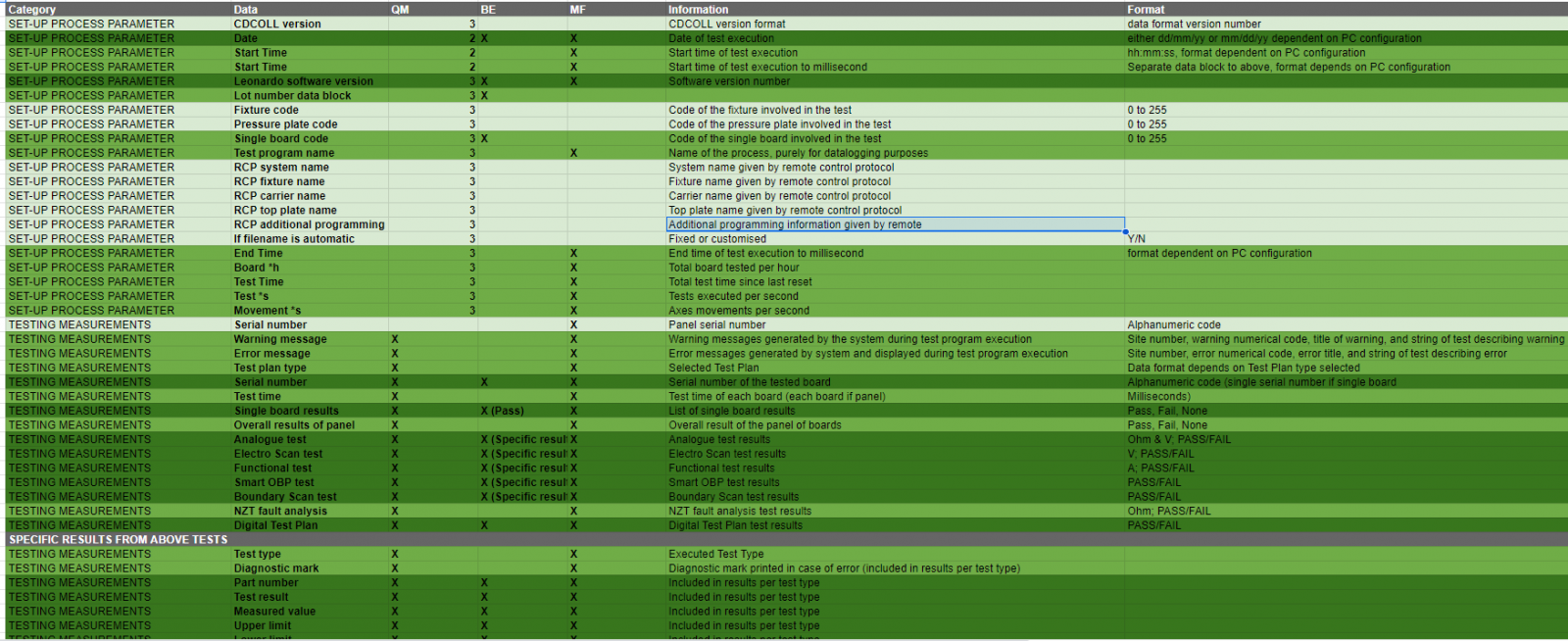

Once all data had been collected and the function and purposes of each machine fully understood, the next deliverable was prioritising the data. This prioritisation was based on data research and meetings with Quality Management, Business Excellence and Manufacturing to determine the needs that need to be met and how they can be met. The following colour-coded table exemplifies the prioritisation of data conducted for all five machines:

Flying Probe Tester

Our Solution

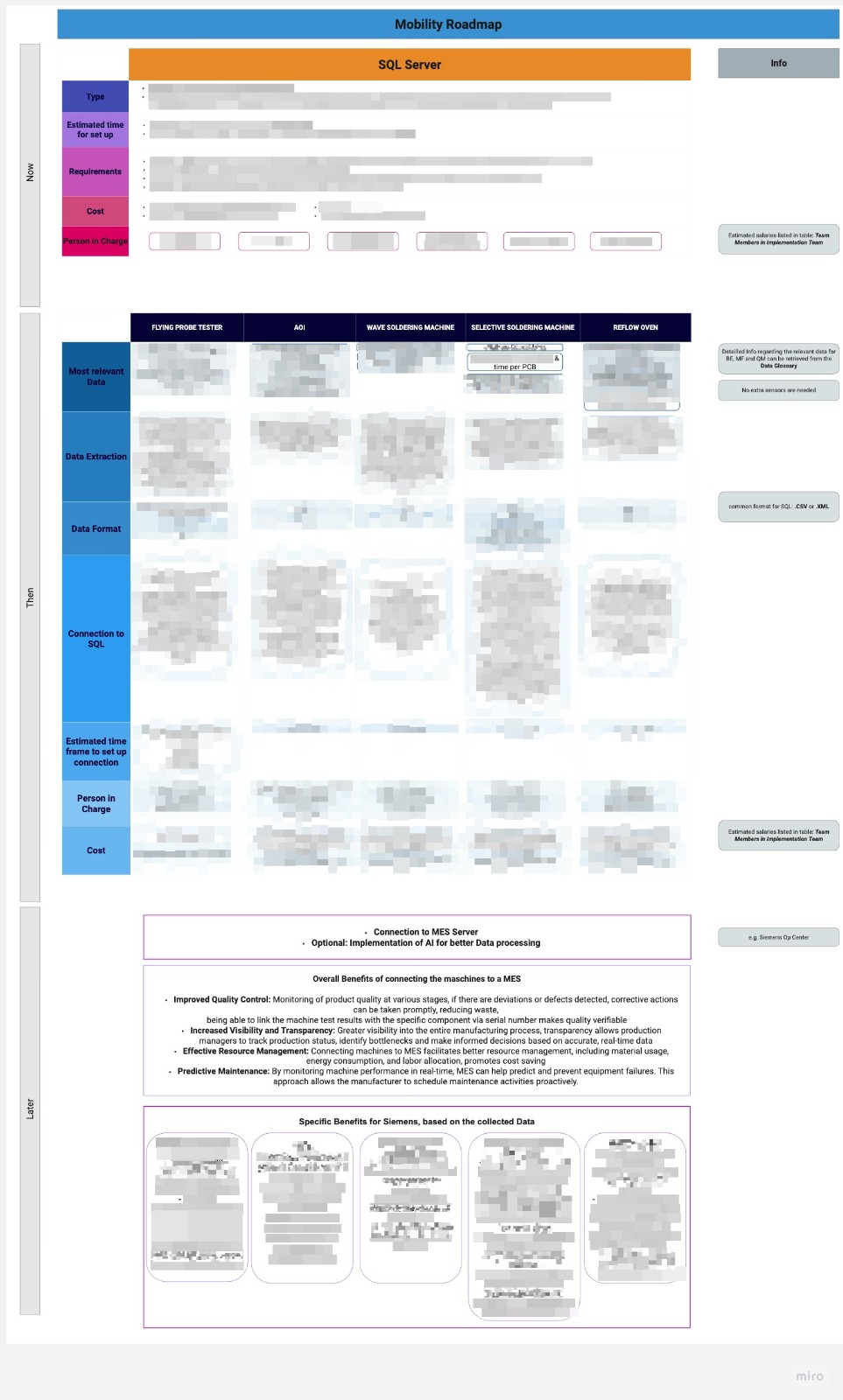

The main, final project result is a roadmap depicting the implementation process of the machine’s connection to a Microsoft SQL server for future connection to Siemens Opcentre. This roadmap prioritises the machines based on the associated value, costs, requirements, and technical feasibility.

The SQL server is a form of relational database system management (RDSM) that will function as an intermediate database for storage of all ‘priority’ machine data. The SQL Server will host structured tables to ensure efficient data storage and retrieval via a script that periodically extracts the machine data. The key benefits associated with implementing an MS SQL server as a solution to providing the Opcenter with access to the selected machines, are as follows:

- Easy to implement

- All selected machines currently use Windows operating systems, eliminating the need for OS transformations or employee training

- Saves time and resources (money and labour)

- Provides robust security features to protect data from unauthorised access

- User friendly tools and interface